Johnson Controls safeguards planning with the help of simulation

Johnson Controls is an internationally successful technology and industrial company offering a wide spectrum of products and services for the building and automotive sector. Its power solutions division is the leading supplier of lead batteries for automobiles and of innovative batteries for vehicles with start-stop function, for hybrid and electric vehicles. World-famous brands like VARTA® are part of the product portfolio of Johnson Controls.

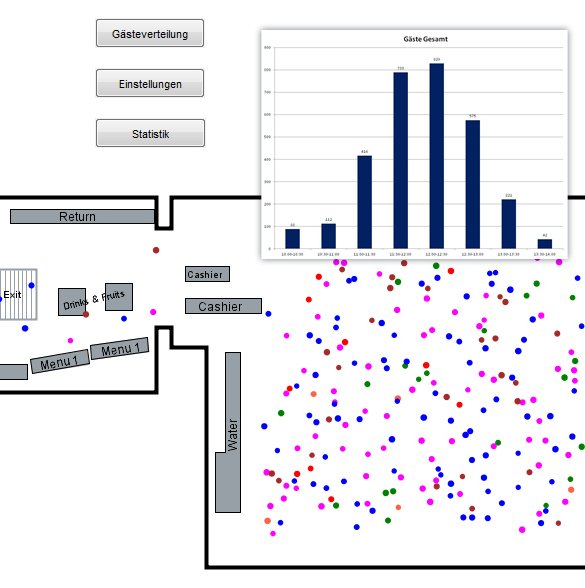

Worldwide demand increases steeply for batteries that are suitable for fuel-efficient start-stop vehicle technology. For this reason, Johnson Controls currently expands its battery assembly capacities. Especially the connecting logistics within the pre-production processes have been examined in detail. The focus was on two central topics:

- is the planned number of furnaces and forklifts in pre-production sufficient?

- how many vehicles are necessary in the driverless transport system in order to safely supply the assembly lines?

The simulation model developed by SimPlan to investigate these questions was able to safeguard the planning by allowing detailed forecasts about throughput and processing times, inventory and the utilization of the furnaces and vehicles. Different scenarios were tested regarding for example the occupancy rate of the furnaces and the number of vehicles needed.

Johnson Controls was able to adjust the relevant parameters in the model and carry out simulation runs independently, in order to gain a detailed understanding of the effects of adjustments. To be able to do this and to safeguard future planning decisions, Johnson Controls had SimPlan train one of their employees to use the simulation software.

The employee accompanied every phase of the project, which enabled him to directly and efficiently learn how to carry out simulation projects, in order to independently undertake future projects for Johnson Controls.